Weld control process in the wheel manufacturing

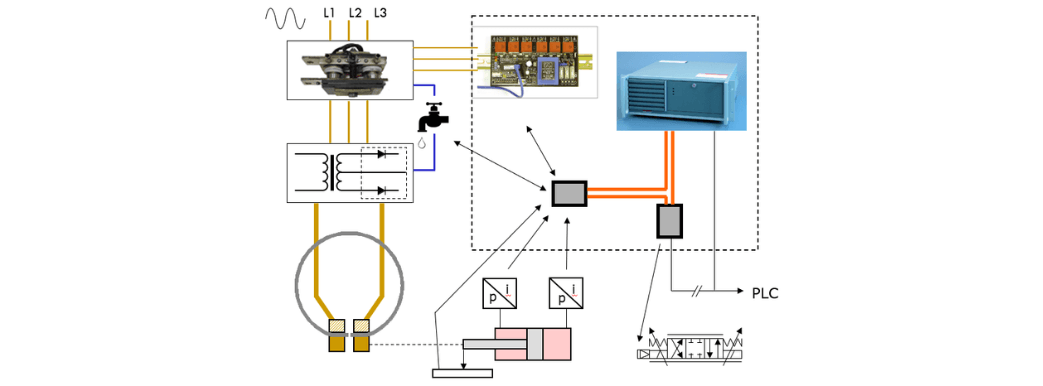

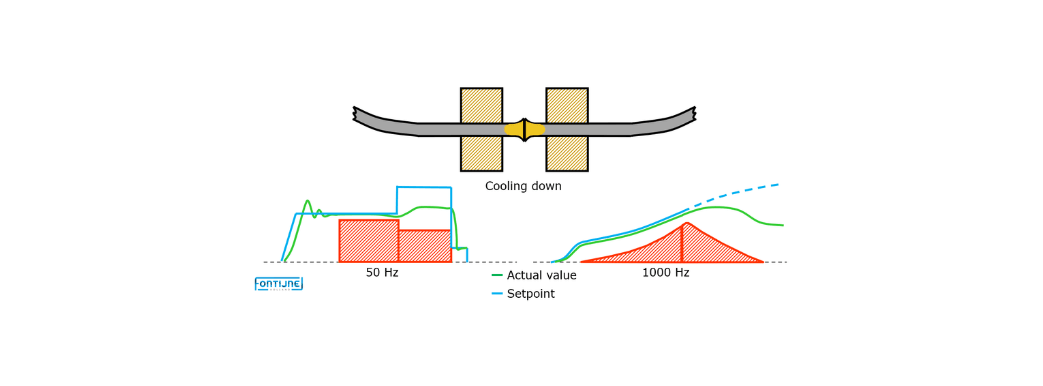

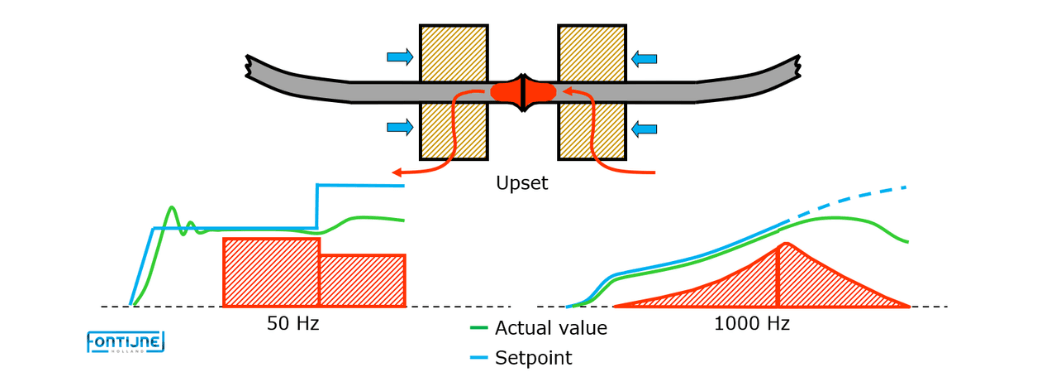

The Fontijne Holland Weld Control 2.0 (1000 Hz) is a unique temperature dependent*, closed loop, control system, which controls the heating phase by heating up the product to the yield temperature while holding the upset force and controls the upset phase by position control to reach the required amount of upset. The welding process is based on temperature, pressure and position. We are constantly developing the Weld Control system over the years, starting with Weld Control 2000 through Weld Control 2009 to Weld Control 2.0. The latest weld control system is designed to operate to its full potential on the state of the art dedicated Fontijne Holland welder. Furthermore, the Fontijne Holland weld control 2.0 (50-60 Hz) operates on all existing flash and flash less DC welders.

* The temperature dependent control requires specific hardware; to use the control system to its full potential the machine should be equipped with high speed servo hydraulic valves, high speed controls, sensors, etc.

The Fontijne Holland weld control systems

Fontijne Holland offers different systems for the weld control depending on your requirements. The latest innovation is the Weld Control 2.0.

Weld Control 2.0

The Fontijne Holland weld control 2.0 combines various weld controls in one program. It has the following unique features:

- It offers a common platform for other brand weld software, weld 2000 and weld 2009.

- Independent from 50 Hz or 1000 Hz transformers.

- Industrial PC hardware independent.

- Better remote support.

- New and updated HMI (Human-Machine Interface).

- Compatible with Windows 10 and newer.

- Designed for 64-bit processors.

The following weld controls can be replaced by the new Fontijne Holland weld control 2.0:

- Weld control other brand, e.g. Blohm + Voss, Kieserling, IBP, Medar, AII Schlatter, Hess.

- Fontijne Holland Weld 2000 (Weld control 50 Hz).

- Fontijne Holland Weld 2009 (Weld control 1000 Hz).

Weld Control 2000

The Weld 2000 has the following unique features:

- Works on all existing DC welders.

- Uses commercially available components.

- Two different welding program interfaces: Schlatter (table) and Medar (instructions) methods.

- Data acquisition of all weld parameters.

- Weld wizard with 7 languages based on Fontijne’s extensive rim welding experience.

- Password protected for user levels.

- Modular build for software upgrades.

- Not affected by electromagnetic interference by using fiberoptic cables.

- Thyristor controlled.

The Weld 2009 has the following unique features:

- Closed loop control.

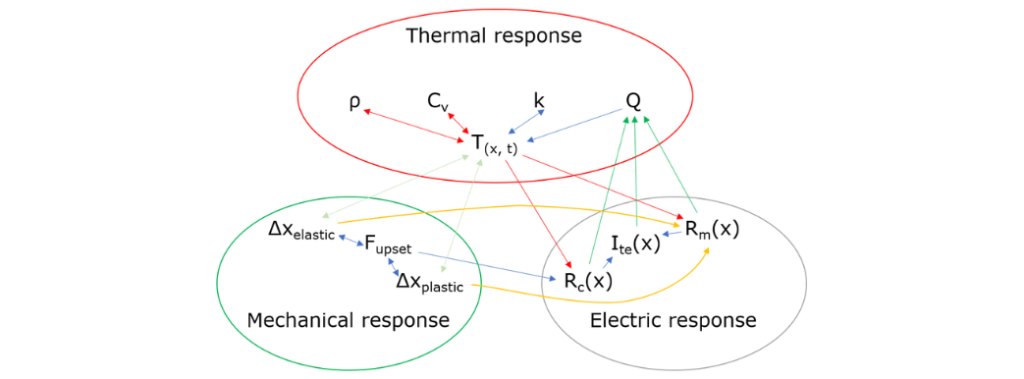

- Weld process based on temperature, pressure and position.

- Program builder.

- Constant upset position.

- Inverter controlled.

- Not dependent on operator settings as the machine determines the process (operator friendly).

- High repeatability.

- Less energy consumption.

- 50 Hz system: 296 kJ.

- 1000 Hz system: 173 kJ.

Not the right one?

The Fontijne Holland weld control, originally designed for wheel production, can also be used for other applications, where a DC welding process needs to be controlled. If you would like to know more about our Weld Control, please feel free to contact us.