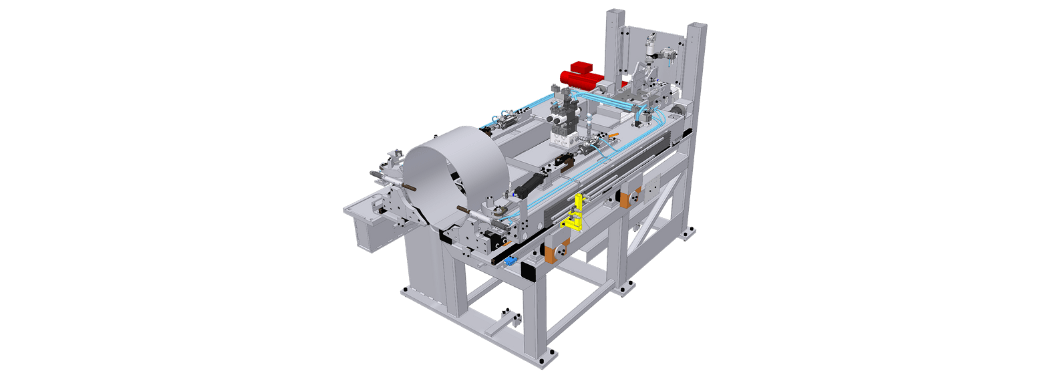

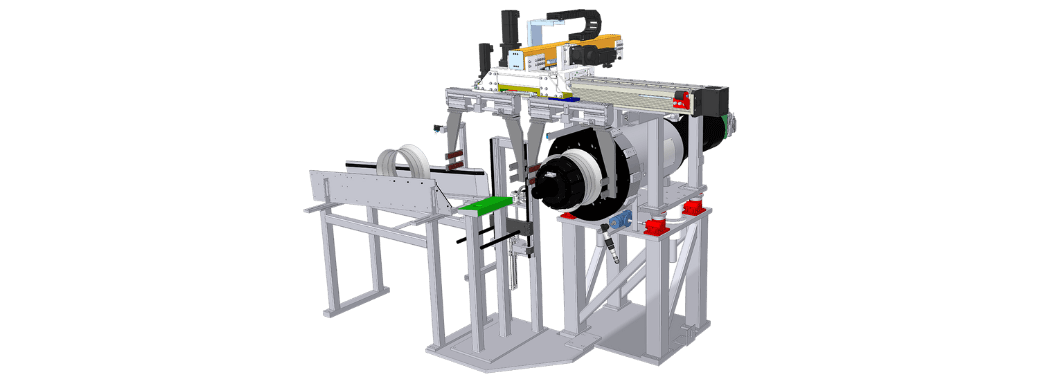

Ring preparation line for passenger car wheels

The ring preparation line forms a high-quality plate to a flared shape ring for the roll forming process. The strip will be coiled very precisely, to guarantee that the ends of the strip are perfectly aligned towards each other.

The TC buttwelding process is executed with a minimum of energy and upset to save energy, material and to reduce the scrap rate (close to zero). TC stands for Temperature Controlled, as Fontijne Holland has the know-how to start the Upset process based on the temperature in the weld.

The buttweld is dressed with innovative process solutions to obtain a perfect weldseam, without excess material and an improved yield strength of the weld affected zone. The welddressed ring will be sized and flared to a perfectly round product with a known diameter. This roundness will have a positive effect on the final runout of the wheel. You can eqipped the ring preparation line with a stacker / de-stacker station for a user-friendly loading.

The Fontijne Holland ring preparation line, originally designed for wheel production, can also be used for other applications, where a steel strip needs to be transformed into a ring.

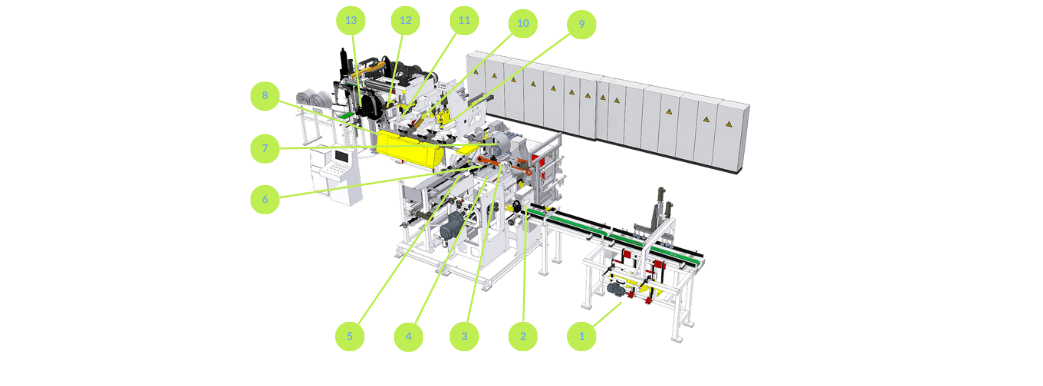

The process steps of a ring preparation line

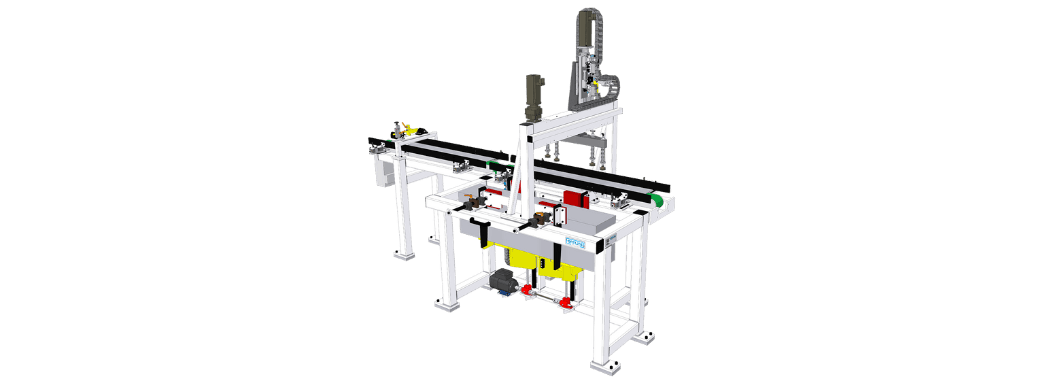

Stacker / de-stacker

The stacker / de-stacker is a buffer which enables a continuous feed of plates to the ring preparation line, also during coil change.

Unique features:

- Plates are divided by magnets to prevent the loading of double plates.

- The machine is equipped with double plate detection to provide redundant safety.

Rotary Marker

The plates can be marked with a code defined by the customer.

Unique features:

- The marker is capable of marking on the left, right, top or bottom side of the product.

- One character at the time is formed, which gives a great benefit to the total marker force needed; it has no relation to the length of the text.

Flattener

The ends of the ring are formed to flat ends, ensuring optimum clamping for the welding process.

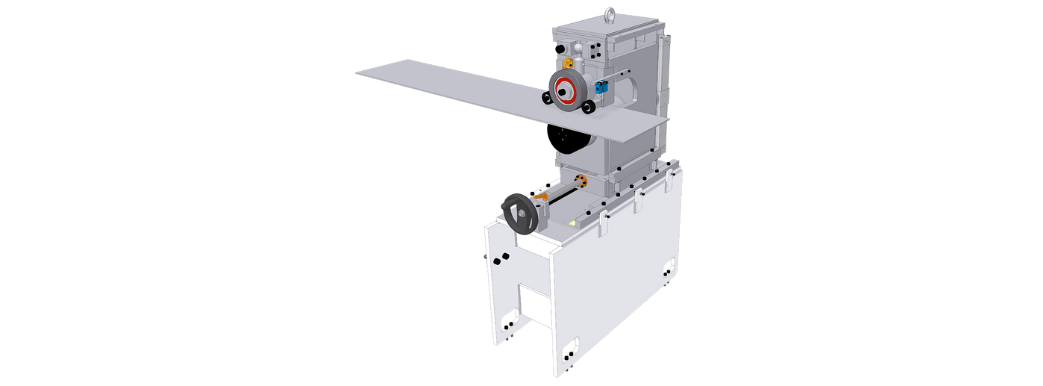

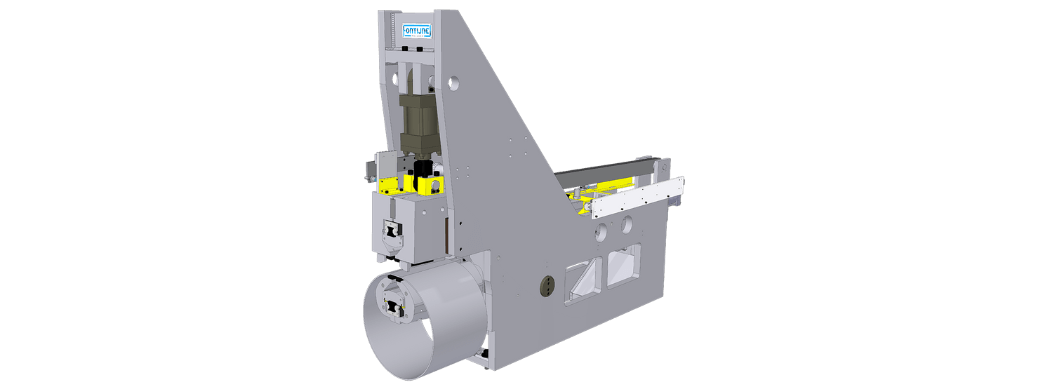

Coiler

The plates are bent in the 3+1 rolls coiler to form a ring.

Unique features:

- The position of the rolls is designed to an optimum for smooth starting of the coiling process.

- It is possible to steer the product by an adjustable fourth roll to obtain a stable coiling process, to control over or under coiling.

- Adjustment to prevent spiral coiling.

Rotor

The perfectly aligned ring is transported and rotated to the welder loader (weld seam at the top becomes weld seam at the bottom).

Unique feature:

- Misalignment in height is leveled.

- During transportation active clamping of the part to guarantee the alignment.

Welder loader

The ring is loaded to the TC-welder.

Unique features:

- The welder loader clamps the ring in such a way that all alignments will be held.

- The gap in the ring will be completely closed to enable welding.

- The ring is lowered to the welder clamp surface (after the horizontal movement) to prevent scratching of the ring surface and to reduce wear on the welder clamps.

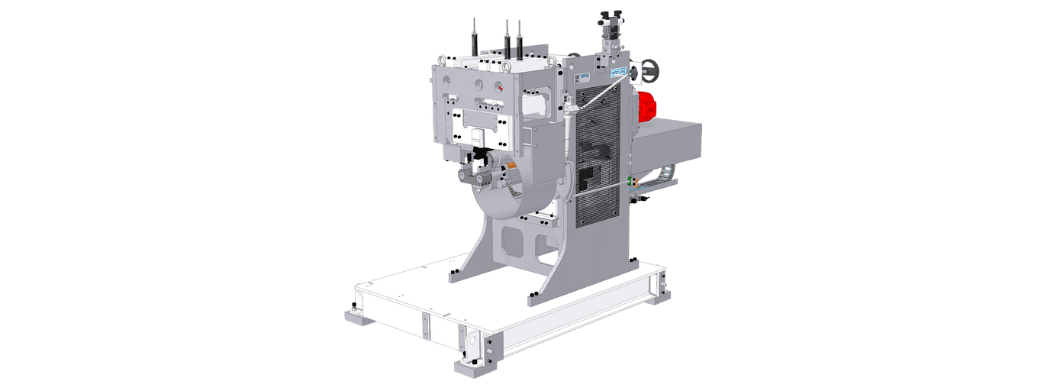

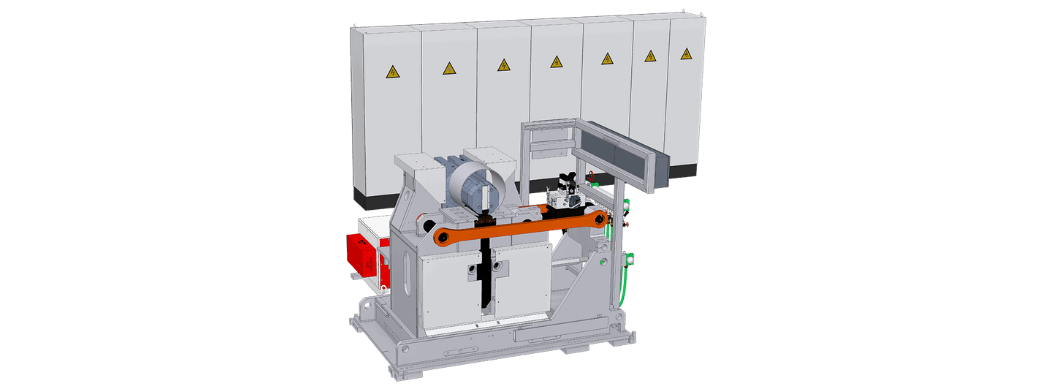

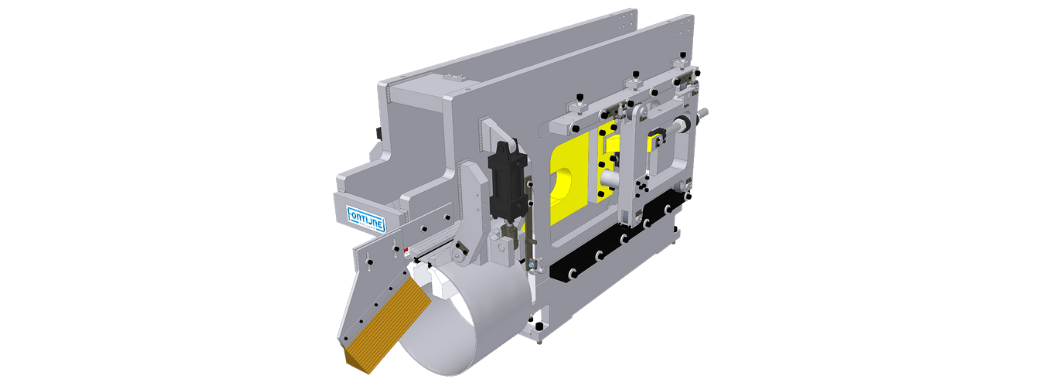

TC Welder

The TC* welder welds the ring. This is the heart of the preparation line, herewith the final quality of the weld will be made.

Mechanically the Fontijne Holland welder offers unique features:

- Center line remains always the same, both clamps are moving.

- Automatic compensation for taper material for an optimized clamping.

- No slides, only rotation points for a better lifetime of the bearings.

- Symmetrical design of busbars and transformer, current left and right are the same.

TC buttwelding is not always possible, due to local circumstances, material or cross-section, therefor Fontijne Holland offers DC welding and DC Flash welding. Mechanically there are no compromises, this is all integrated in our innovative weld control platform.

*TC stands for Temperature Controlled, as Fontijne Holland has the know-how to start the Upset process based on the temperature in the weld. The unique features weld control 4.0 are:

- Open loop weld control for DC Flash and DC Flashless welding.

- Closed loop weld control system to determine the welding temperature, applied force and upset speed, resulting in a perfect weld in an extreme short time Transformers based on 50 – 60Hz or MFDC 1000Hz systems.

Transfer

The ring is automatically transported from trimmer to cooling station.

Unique feature:

- The transfer is designed in such a way that the ring first is lifted from the surface of each machine, before it is transported to the next station preventing damage to the product and to ensure longer life of all machine clamps.

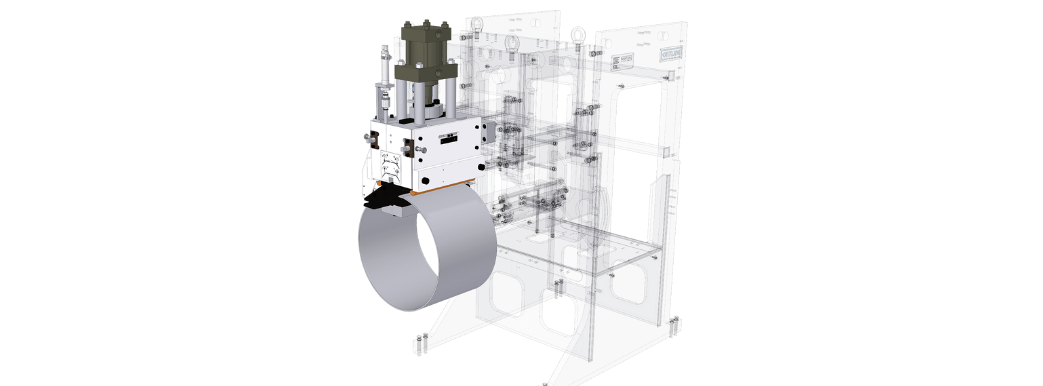

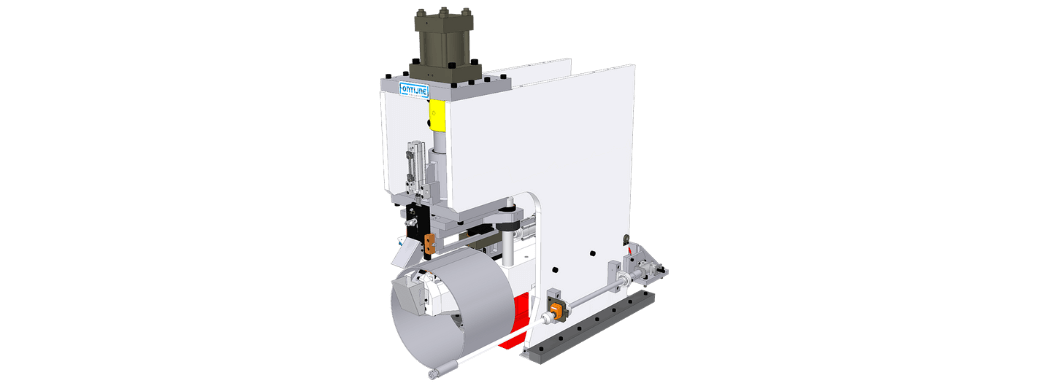

Weld Trimmer

After the welding process the inside and outside of the weld is trimmed.

Unique features:

- The cutting plates are placed in easy removable cassettes.

- The height of each individual cutting plate can be adjusted.

- No adjustments needed for different material thicknesses.

- Automatic compensation for tapered material.

- The chips are collected and guided to the bottom of the machine to prevent them from falling into the ring, causing damage in the next steps.

Weld Seam Roller (Planisher)

The Weld Seam Roller remains the height difference after the trimming process.

Unique feature:

- Adjusting the roll force is easy and precise.

- The rigid construction for applying the press force ensures a stable rolling process.

- The roller shape guarantees planishing the material without marks.

Side Trimmer

The bulges at the front and the rear of the weld are removed by the side trimmer.

Unique features:

- Each ring is automatically aligned for the width.

- The cutting radius is designed in such a way that after roll forming no bulges remain.

- The chips are collected to prevent them from falling in the ring, causing damage to the ring in next steps.

Cooling station

The weld is cooled to ensure a homogeneous behavior of the ring material in the flaexpander process.

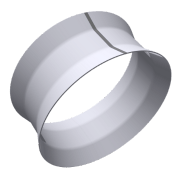

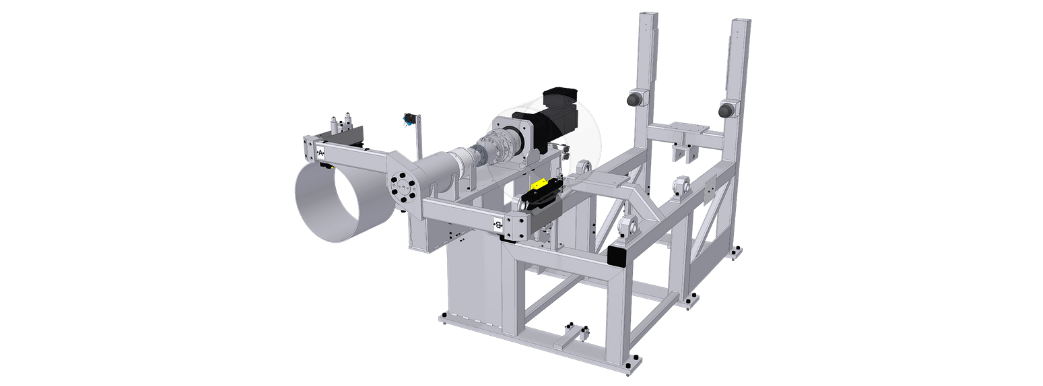

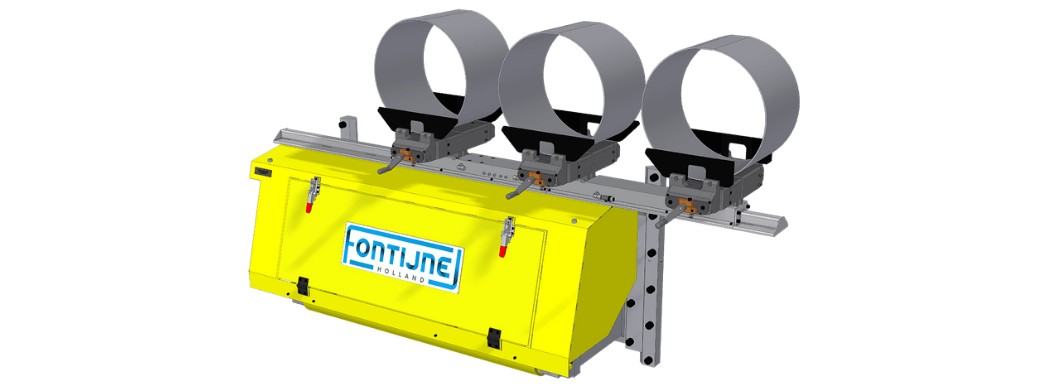

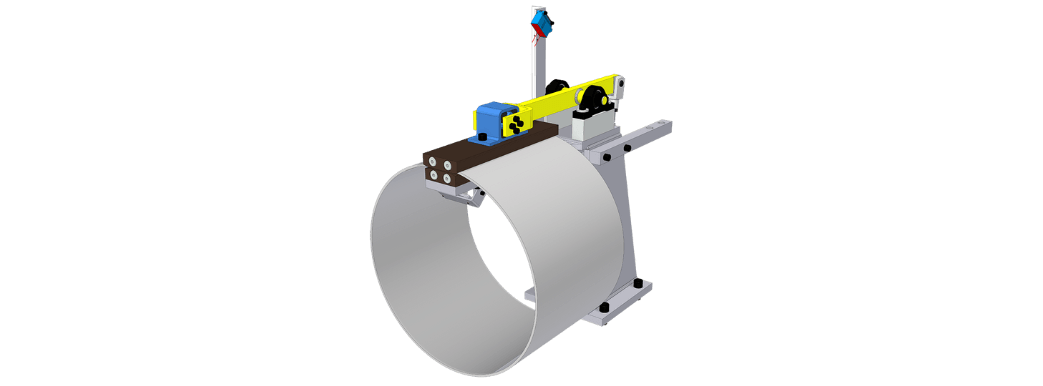

Flaexpander

Finally the ring is re-rounded and flared.

Unique feature:

- Re-rounding and flaring in one machine.

- Diameter control during sizing of the ring.

- Spring back compensation.

- Perfect roundness of the ring.

- No axial force applied during flaring, only radial force.

- No friction during flaring, means no marks or scratches.

- While flaring, crack detection in the welding zone is executed to guarantee the quality of the product.

Not the right one?

The Fontijne Holland ring preparation line does not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.