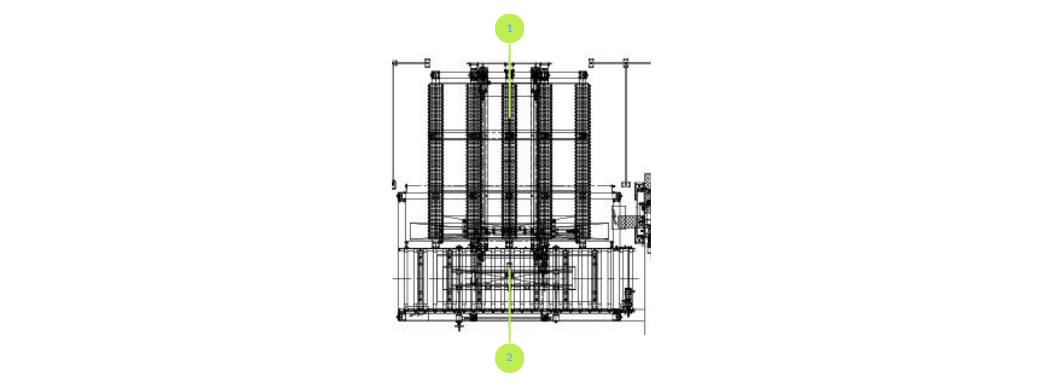

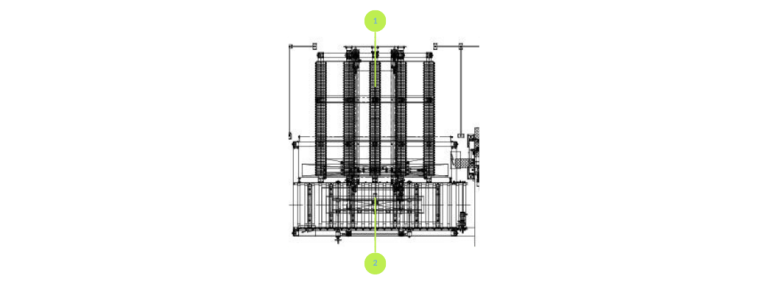

Stacker / De-stacker

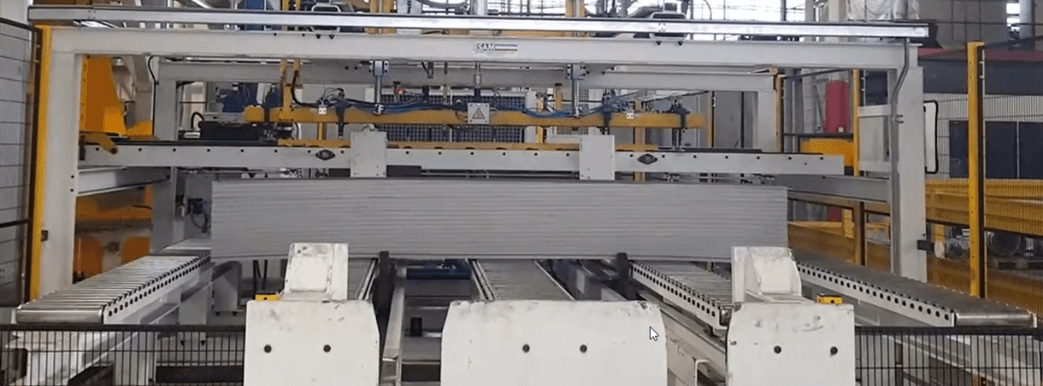

The stacker / de-stacker is a buffer which enables a continuous feed of plates to the ring preparation line, also during coil change. The machine is designed to operate with a fully automatic production line: The coiler triggers the need for a plate. Extra available plates are stored for later use.

The Fontijne Holland stacker / de-stacker, originally designed for wheel production, can also be used for other applications, where plates need to be stored and unstacked automatically.

Loading

The plates are transported to the stacker / de-stacker by a conveyor.

In case of a single de-stacker station the operator can load up to 3 stacks of strips. The stack is moved to the de-stacking position automatically.

De-stacking

When de-stacking, the strips are picked and placed one by one on the infeed conveyor.

Unique feature:

- The machine is equipped with double plate detection to provide redundant safety.

Not the right one?

The Fontijne Holland lines do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.