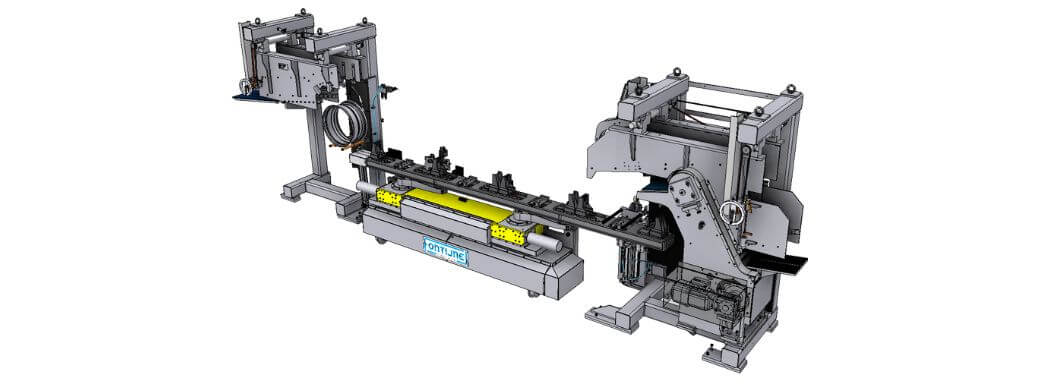

Rim forming line for commercial vehicle wheels

A ring forming line is designed to transform a flared ring into a perfectly round and profiled rim. The flared ring will be formed into the required profile in three steps, guaranting high output, low wear on tooling and a perfect, unscratched surface of the rim. The final expander calibrates the ring to a perfectly round profiled shape.

The Fontijne Holland rim forming line for commercial vehicle wheelsproduces a high quality, perfectly round rim with the required profile. Originally designed for wheel production, the line can also be used for other applications, where a ring needs to be rolled to a profiled product.

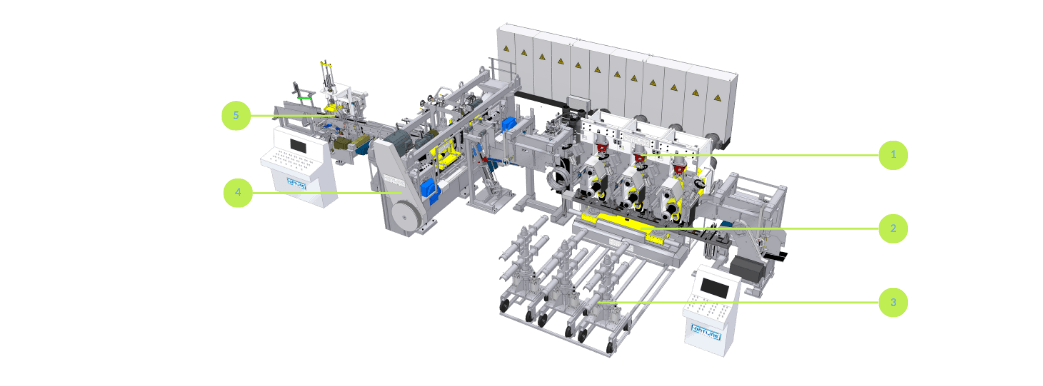

The process steps of a rim forming line

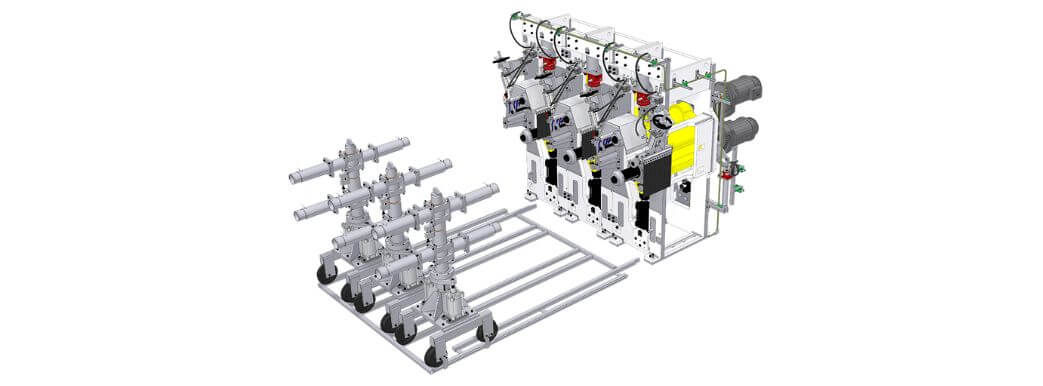

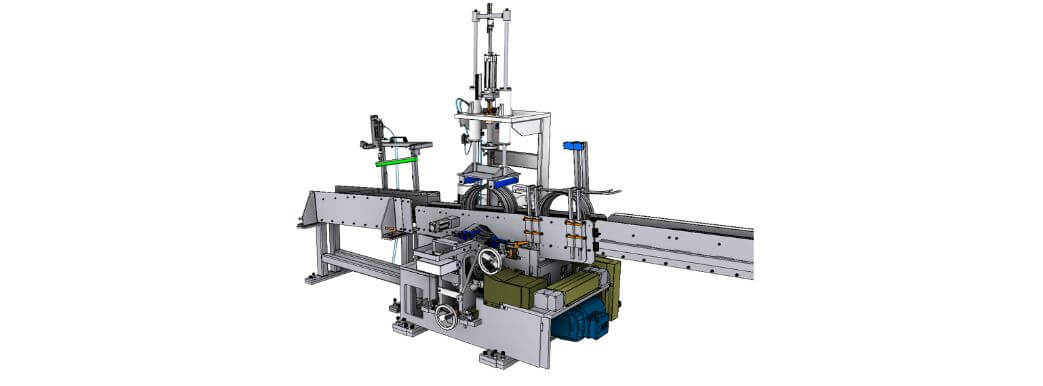

Roll formers

The roll formers form the profile in the ring.

Unique features:

- The rotary movement is executed by energy efficient, electrical driven spindles.

- The tilting of the upper and lower spindles can be adjusted.

- Optional quick locking/releasing mechanism for fast tool change (no auxiliary tools needed). This method of clamping enables optimum centering of the tooling to the shaft resulting in a perfect true alignment.

- Compact and rigid design with small “foot print”.

- Unique bearing design guaranties long life, play-free axial location of the spindle shaft.

- Axial adjustment for optimum control of alignment of upper and lower tooling.

- New development for the “green line”: a sustainable design for the roll former consisting of a fully electric operating machine without any hydraulics. Beside the spindles also the infeed stroke is electrically driven.

Roll former loader

The rims are loaded and unloaded to the roll formers by a loader beam.

Unique features:

- The rims are supported during the transfer movement to prevent tilting during acceleration and deceleration.

- Very precise loading position resulting in no oscillation of the ring when picked up by the lower spindle.

- Unique movement path of the loader beam to enable compact position of roll formers next to each other and to ensure perfect centered loading.

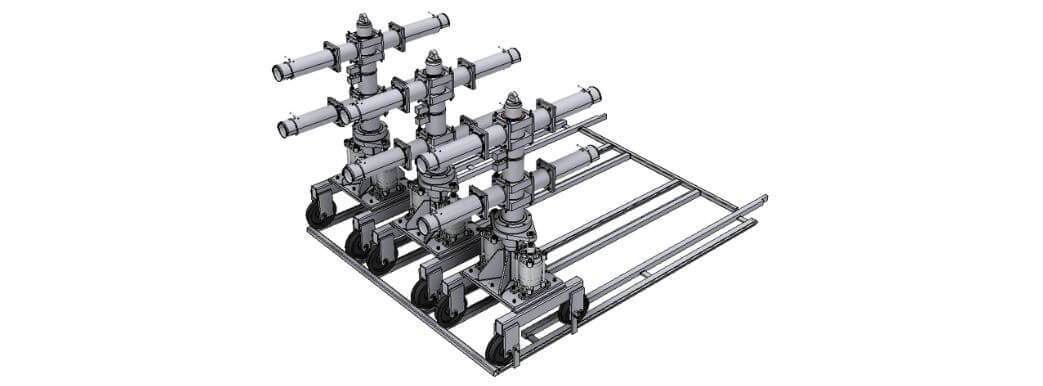

Tool changers

Optionally the roll formers can be equipped with auxiliary tool change devices.

Unique features:

- The new tooling can be placed on one side, the old tooling slides to the other side of the tool changer.

- No lifting is needed.

- Enables fast tool change times.

- Safe for operators.

Final expander

The final expander calibrates the rim by sizing it to a final dimension with a perfect roundness.

Unique features:

- Quick change procedure of expander heads.

Rim edge conditioner

Burrs on the edges of the rim (occurring during the roll forming process) are eliminated by the rim edge conditioner.

Unique features:

- Energy efficient electric drive of the edge rolls.

Not the right one?

The Fontijne Holland rim forming line for commercial vehicle wheels does not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.